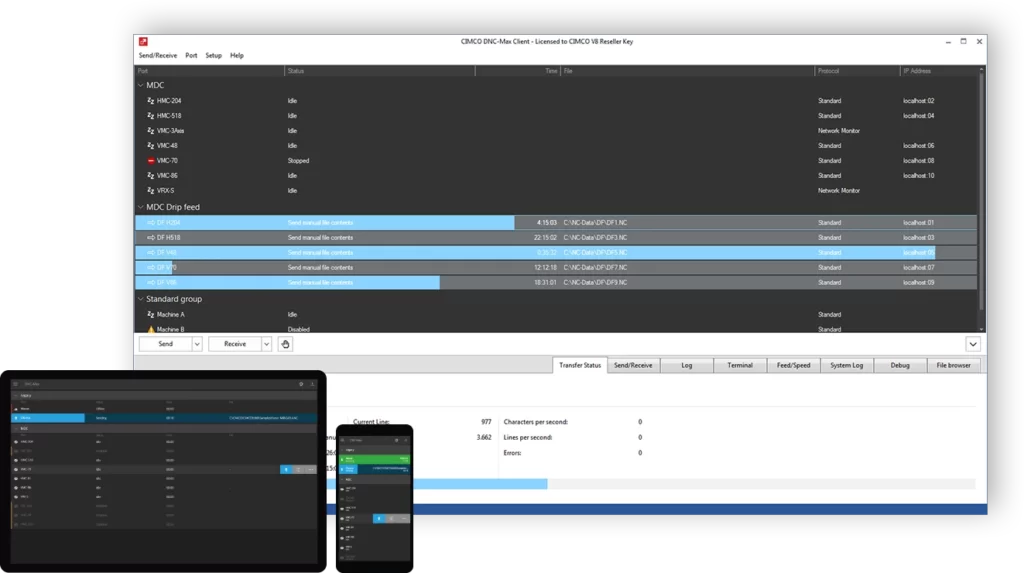

DNC Communication for CNCs, Robots, PLCs and more

Leading DNC solution

BENEFITS

Network CNCs, PLCs & Robots

Connect all your manufacturing equipment in one network using industry standard hardware, including Ethernet and Wireless serial device servers, traditional card based hardware, and existing legacy hardware.

Works with your files

Whether you set up your first DNC system or you replace an existing, the DNC application you choose must be compatible with your data. DNC-Max eliminates the need to update all your existing NC programs.

Access programs immediately

With DNC-Max there is no waiting. All your machines can download programs at the same time.

Download programs remotely

Reduce downtime from walking programs out to the shopfloor. Initiate downloads of part programs directly from the machine’s CNC control, from any modern mobile device or using a Barcode reader.

Ease of use and administration

File transfers, port monitoring and system administration are all performed in a clean, intuitive client/server interface which is part of the system’s intelligent, solution driven design.

A scalable solution

DNC-Max scales with your company. Upgrade with integrated manufacturing file management (CIMCO NC-Base/MDM) and manufacturing data collection & machine monitoring (CIMCO MDC-Max).

FEATURES

Ports, status and organization

Ports are used to define machine connections and shows the current port and machine status. Organize ports in groups for optimal overview.

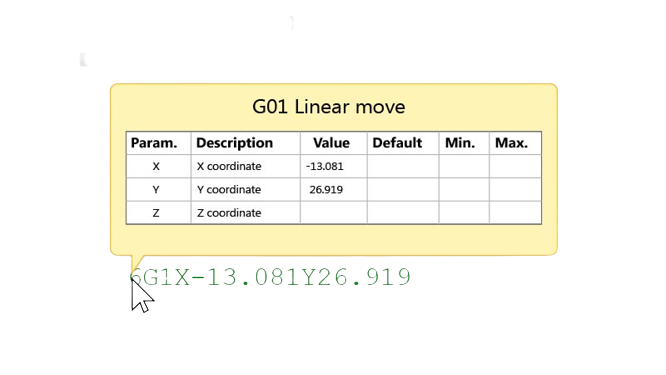

Network protocols

Supports both standard and specialized network protocols to communicate with most manufacturing equipment. Mazak, Deckel, Agie, Fagor, Brother, Modbus, and many more.

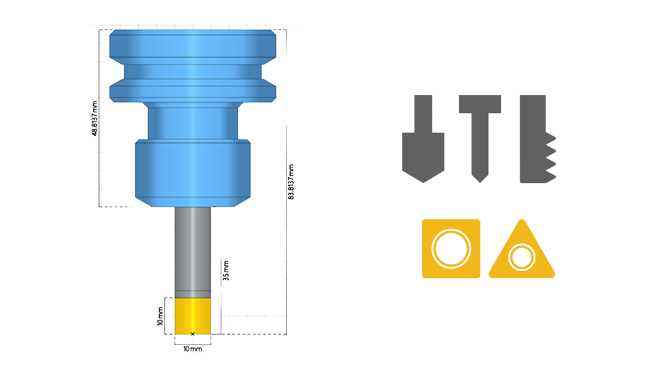

Send, receive and dripfeed

The Send Queue ensures that files are transferred sequentially. Advanced options available for unlimited filesize dripfeeding if supported by CNC.

Remote request

Request programs directly from the CNC control or mobile device. Supports DNC restart and file looping, directory support, directory prioritization, filters, wildcards, and more.

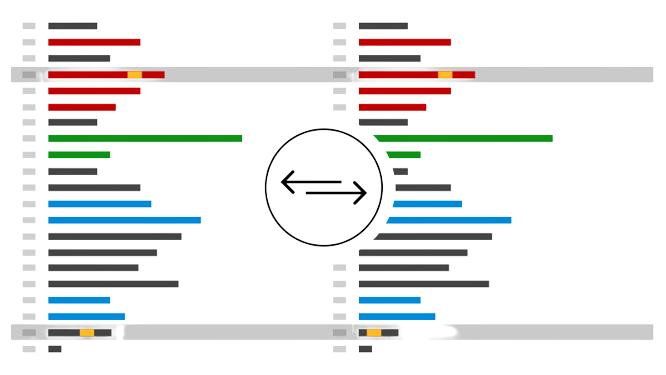

Versioning

Programs that are modified on the CNC control (or elsewhere) can be raised in version and stored in a quarantine area for review. Easily track changes and revert to previous versions.

User access control

Control the level of access for users on both the DNC-Max Server and Clients. Limit configuration and control options to key personnel.

Logging and notifications

Real-time logging of DNC system and machine activity. Send status reports and notifications directly to CNC operators and key personnel.

CNC and hardware compatibility

Works with industry standard RS-232 serial hardware, Ethernet and Wireless serial device servers, traditional card based hardware, and existing legacy hardware.

Integration with CIMCO Edit

In addition to the stand-alone PC and Web Client, DNC-Max is also available as an add-on for CIMCO Edit providing a seamlessly integrated application interface.

ALL FEATURES

System components

Compatibility and updates

Ports and network protocols

File transfers

Remote request

Security, logging, versioning

BROCHURES

CIMCO DNC-Max Overview

English

CIMCO DNC-Max Overview

German