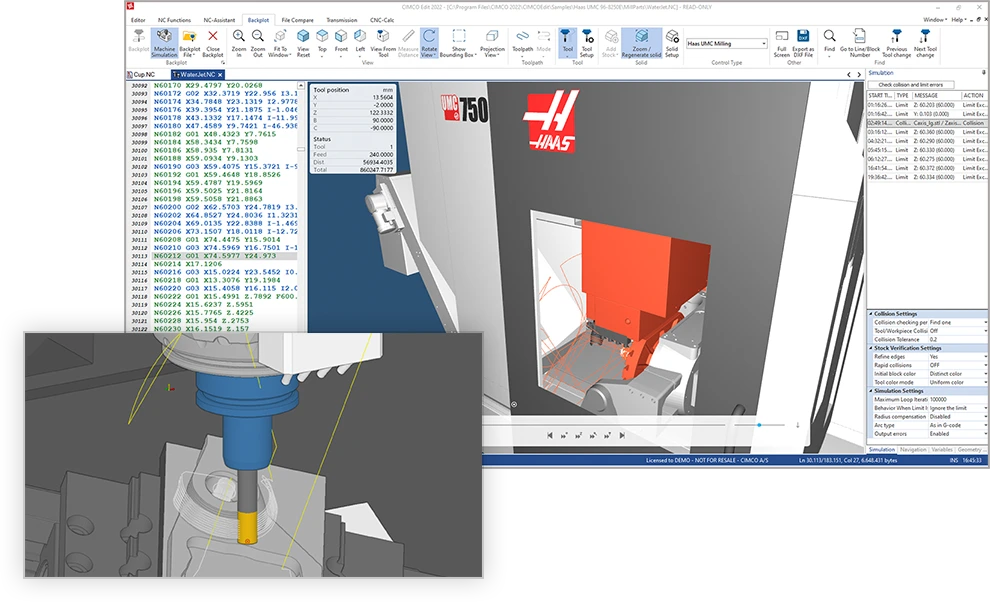

NC program simulation on 3D machine models

Simulate programs on machine models

Machine Simulation is an add-on for CIMCO Edit and a powerful addition to the existing Backplot.

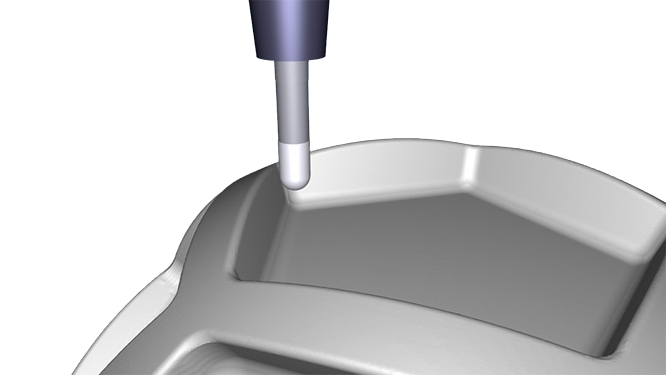

Prove-out your NC program on a 3D model of your CNC machine and see the exact movement of components such as heads, spindles, and even peripheral devices. Collisions and out of limit moves are automatically detected to ensure that error-free code is sent to the physical machine.

BENEFITS

Shop safety

Protect employees from hazardous situations and your machines from costly damage by simulating and testing your NC programs on PC before running them on your physical machines.

Accelerate startup

Reduce the time spent on job setup and scrap from initial test runs and calibration. With your NC program thoroughly simulated and tested on PC, you can run your program with confidence the first time.

Faster iterations

Optimize your programs by quickly trying out new ideas and testing your modifications on PC. Save time, resources, and wear on your machine tools.

Faster shifting between machines

Need to shift a job to a different machine? Seamlessly switch between your machine configurations, adjust your setup and simulate your NC program to check for any issues prior to cutting on the physical machine.

Train at the PC instead of at the machine

Use the available 3D simulation and NC editing functions to train employees in operating machines and modifying NC code.

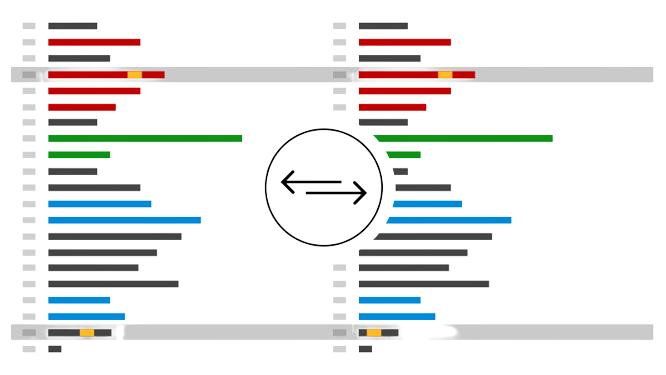

Simulation and NC editing combined

Developed as a fully integrated add-on for CIMCO Edit which combined provides a powerful solution for doing fast iterations of simulating and fixing problems in your code.

FEATURES

Full control of simulation

Analyze the simulation of your NC program from any angle or distance using zoom, pan, and rotate. Adjustable speed slider in both directions. Jump to next/previous tool, cutting pass, or move.

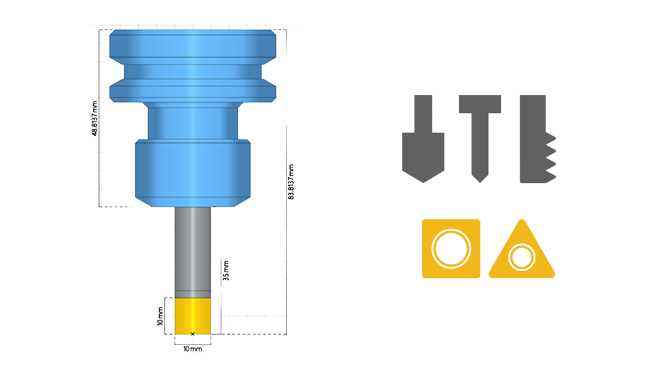

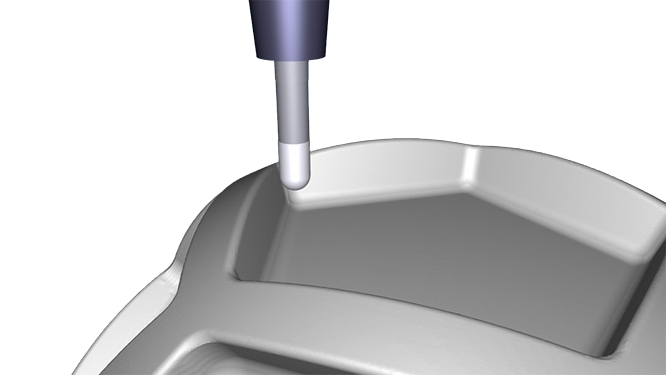

Stock material removal

High and low tolerance options for simulation of stock removal based on your NC code. Includes multiple options to define the stock, or import your stock as an STL file. The resulting stock can be exported as an STL file.

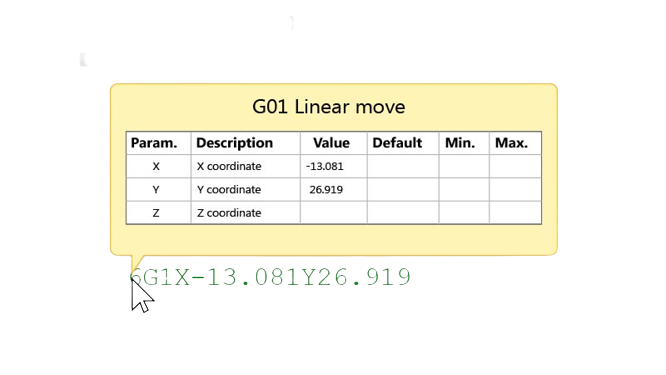

Inspection

Side-by-side display of your NC code, simulation and Simulation Report. Whilst simulating, individual components will highlight red informing you of any collisions. All collisions, out of limit moves and program errors are automatically detected and recorded in the Simulation Report.

Simulation Report

The auto-generated Simulation Report provides a detailed list of all errors found within your NC program. Select any reported error and jump directly to the corresponding line causing the error. Modify your NC code and the Simulation Report will update removing the error and verifying that the problem is resolved.

Downloading Machines

Download and install machines including models directly from within CIMCO Edit and Machine Simulation. Includes many preconfigured machines from vendors such as Haas.

Machine Configuration Editor

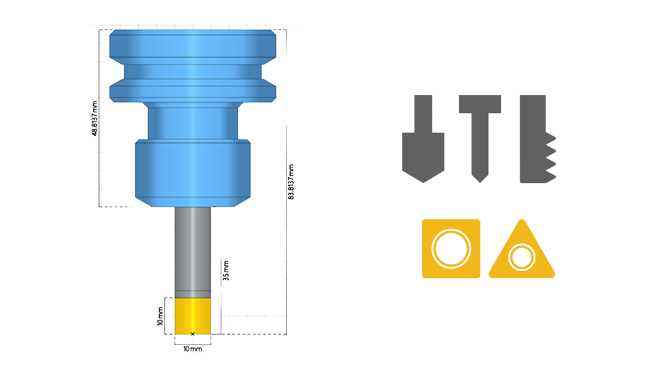

Use the Machine Configuration Editor to configure your own specific machine (if not already available for download). Add model geometry to components and set the machine’s axis, travel limits, feedrates, and tool change positions. Support for 3, 4 and 5-axis milling machines are available.

Geometry Manager

Machine definitions are visualized in a machine-tree where properties of components such as head, table, and workpiece can be viewed, or visibility toggled.

Scanning Commands

Automate the task of creating tools, loading geometry, specifying work offsets and defining stock when starting Machine Simulation. All of these, and more, can be defined using Scanning Commands in your NC program or an external file.

CAM integrations

Seamlessly transfer tool, holder and geometry data directly from Mastercam, SolidCAM, or other supported CAM systems to CIMCO Machine Simulation or Backplot. Make changes in your CAM system and easily update and reflect the change in CIMCO Machine Simulation or backplot.

BROCHURES

Machine Simulation Overview

English