Production scheduling and order tracking

Shop floor driven

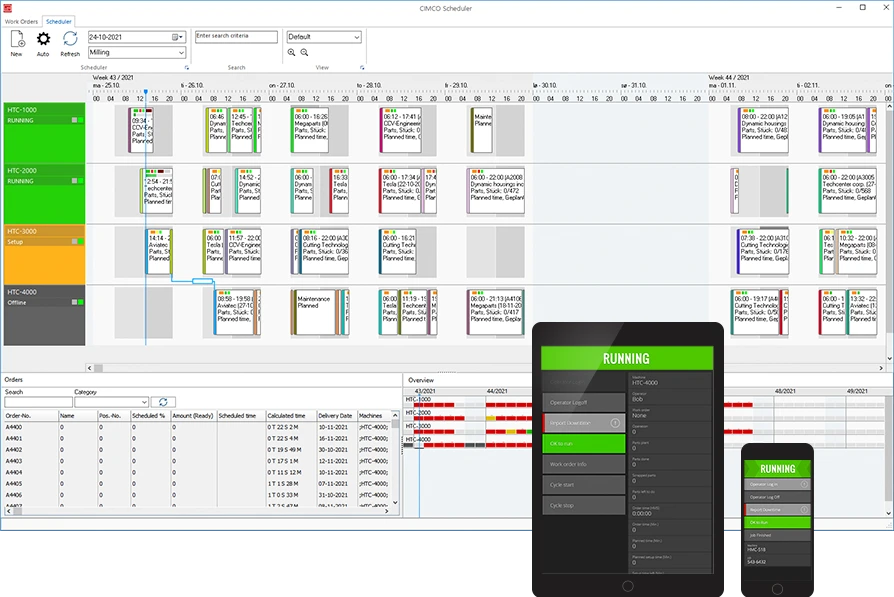

Bator Scheduler provides a central planning board that is driven by real-time data from the shop floor.

Using a specialized mobile interface, machine Operators can provide status updates about orders and machines, which is then instantly reflected in the main planning software and digital signage such as Live Screens and Dashboards.

BENEFITS

Manage all orders in one application

Easily plan, organize, and track all your planned orders in one application that’s driven directly by the actual activities on your shop floor.

Increase delivery accuracy

Increase the accuracy of delivery dates with a complete real-time overview of all your planned orders, machine capacity, shifts, and more.

Real-time order status

Follow the status of orders in real-time and instantly see the consequences of machine downtime on dependant and following orders.

Eliminate production bottlenecks

Get an overview of your machines’ capacity, multi-machine orders and dependencies to avoid bottlenecks and costly downtime.

Identify untapped production capacity

Get the most out of your machines and production by knowing exactly when your machines are being used.

Allows for preventative maintenance

Know when to schedule machine maintenance to avoid critical downtime when it’s time to deliver.

FEATURES

Timeline-based

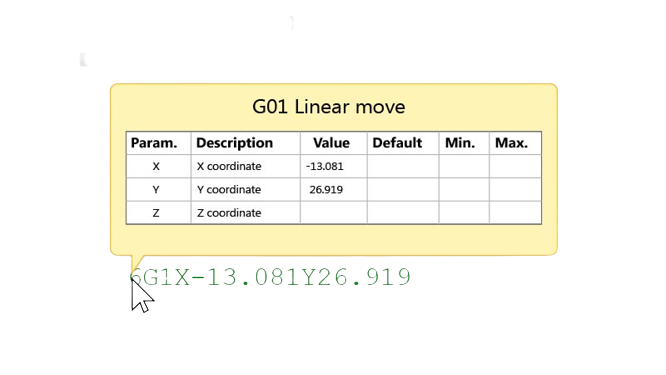

Timeline-based overview of machines, orders, and dependencies over several weeks. Each machine has its own row with machine status, orders and shifts. Dependencies are shown as lines between orders.

Order status at a glance

Real-time overview of order and machine status. Orders have indicators and progress bars to show the status of operation, material availability, and delivery. Information can be directed to TV screens for open space monitoring and digital signage.

Machine capacity overview

View the available production capacity for all your machines over weeks and months. Each day is colored to indicate available capacity.

Automatic scheduling

Auto-schedule orders by either placing new orders after the last one scheduled or by placing them further ahead where there is available capacity. Start and end dates can be simulated before scheduling for production.

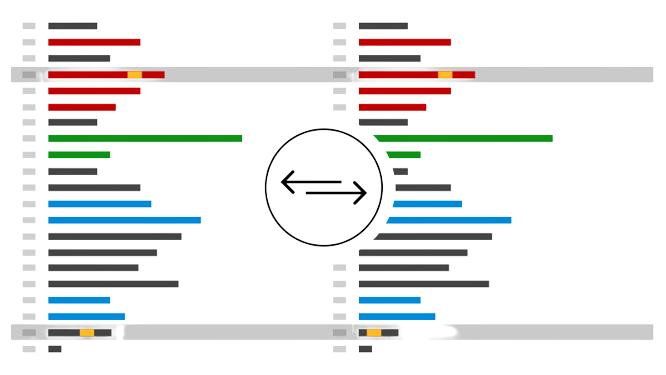

Rescheduling orders

Modify or delete orders directly from the Timeline or drag-and-drop orders between machines. The consequences of a change are presented for approval before an order, and any affected orders, are automatically rescheduled.

Operator interface

Update order and machine status directly from the shop floor with the Operator interface. Display key order data, start/stop orders, set machine status, or enter reasons for downtime.

Maintenance

Schedule Planned Maintenance similar to orders. If the system is notified that a machine is down, Unplanned Maintenance is auto-inserted in the Timeline and the remaining part of an order, and subsequent orders, are pushed back.

Reports

Create custom reports from your order data with the template-based reporting system. Reports can be printed or exported, and templates can be customized with the desired information, layout and style.

Import orders

Auto-import orders from an external system such as an ERP system (using XML formatted data). Use the automatic scheduling feature to quickly simulate and schedule imported orders.

ALL FEATURES

Visual planning board / Timeline

Order and capacity overviews

Bator Scheduler presents an overview of unplanned orders and an overview of available production capacity. For easy access, these overviews are positioned in the bottom part of the interface, below the Timeline.

Planning of orders

Automatic scheduling / Simulation of orders / Import (ERP)

Rescheduling orders / Drag and drop

Dedicated Operator interface (PC and mobile)

Digital signage / Monitoring

Reporting

Security

System components

BROCHURES

Scheduler Overview

English

Scheduler Overview

German