Manufacturing Data Collection (MDC) and Monitoring

CIMCO MDC-Max is the complete MDC solution that enables automatic collection of manufacturing data from machines and personnel in real-time. MDC-Max provides accurate data for identifying causes of production loss, potential areas of improvement and enables real-time monitoring of your shop floor for continuous improvement.

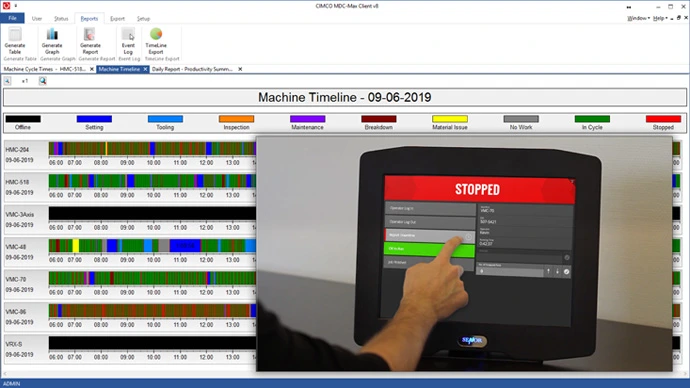

Generate reports and charts with automatic calculation of OEE, cycle time, idle time, setup time, downtime and more. MDC-Max features real-time machine monitoring with Live Screens and has a fully customizable Operator interface for entering downtime reasons directly at the machine.

MDC-Max can benefit the one man operation with a few machines and the corporate enterprise with multiple factories. The MDC-Max software is highly flexible and easily customized to fit your current and future data collection needs. Since MDC-Max is a networked solution that stores data on a central server you can monitor production from multiple locations and access the data from anywhere.

BENEFITS

Improved efficiency

Understand the performance of equipment and personnel with accurate real-time data collection. Identify causes of production loss and potential areas of improvement for better utilization of resources and data-driven process adjustments.

Accurate data collection

Eliminate manual, time consuming and often inaccurate data collection by automating and streamlining the data collection process.

Real-time monitoring

Monitor and visualize the performance of equipment and personnel to improve response times, identify potential errors early, and improve overall company communication. Improve operator engagement through data-driven awareness.

Real-time and historic reports

Eliminate guesswork. Understand the inner workings of your production with customized real-time and historic reports including machine downtime, OEE and other essential KPIs.

Reduce administration time

Reduce paper reliance and administrative time. Update your ERP, MES or other administrative system directly with real-time data as it is received from equipment and personnel.

Access your data anywhere

Access data from one or more sites directly from your mobile device. Easily check the status of equipment or any other information critical to your operation.

FEATURES

SYSTEM COMPONENTS

AUTOMATIC / MANUAL DATA COLLECTION

REAL-TIME MONITORING / DIGITAL SIGNAGE

ANDON / NOTIFICATIONS

DOWNTIME TRACKING / OPERATOR FEEDBACK

REPORTING / KPI / OEE

The flexible reporting system in MDC-Max is designed to support a wide variety of custom reports to meet the requirements of any operation. Visualize data in tables, pie or bar charts, add in production targets, work shifts and calculate any KPI, based on user-defined formulas, such as OEE, MTBF, MTTR, and more.

Examples of reports:

- Overall Equipment Effectiveness (OEE)

- Cycle time per part (min, max and average)

- Number of parts per shift/operator

- Number of defective/scrapped parts

- Machine downtime

- Scheduled maintenance

- Unscheduled maintenance

- Setup time per part

- Machine Operator Efficiency

- Mean time between failures (MTBF)

- Mean time to repair (MTTR)

SECURITY / USER MANAGEMENT

NETWORK SUPPORT / MACHINE CONNECTIONS

INTEGRATION WITH EXTERNAL SYSTEMS / ERP / MES

BROCHURES

MDC-MAX Overview

English